While the scientific community has been hard at work developing new fuel cell and electrolysis technologies to make hydrogen energy a reality, hydrogen cannot fully step into its role unless issues like resource consumption and the societal and environmental impacts associated with developing, manufacturing, and using these technologies are well understood.

The purpose of the European eGHOST project, launched in 2021, was to investigate PEMFC and SOFC systems from an ecodesign and sustainability perspective to make sure that they are designed not only for safety, performance, quality, but—equally—for their impacts on the environment, society, and the economy.

What makes the project unique are the deliverables: a set of guides to help hydrogen stakeholders put these principles to work. The results of the research and, specifically, analyses of the environmental, societal, and economic impacts of hydrogen systems, will inform these useful guides.

The test case for the project is a 48 kW* fuel cell stack and its entire value chain deployed in a scenario representative of a hydrogen-powered vehicle in service. The data on raw materials, energy consumption, and other parameters is gathered by a partner company and then used to feed a model that generates the environmental, societal, and economic impact indicators.

|

|

Contribution to climate change for the manufacturing of one PEMFC stack 1160 kg CO2eq. / stack 48 kWel | PEMFC stack cost distribution according to the production rate

|

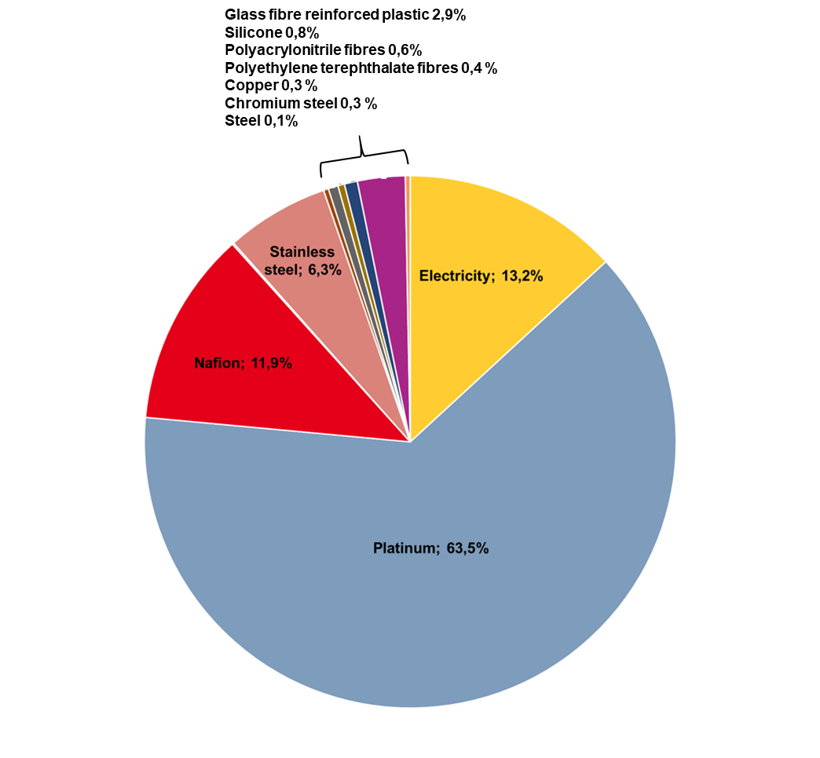

According to the calculations, for a production volume of 50,000 stacks/year, each stack costs €2,233 to manufacture, a figure that is mainly influenced by the number of units produced. The product's carbon footprint was estimated at 1,160 kilograms of CO2 equivalent, 63.5% of which can be attributed to the electricity used to process the platinum in the stack, based on a scenario in which only virgin platinum mined in South Africa is used. However, scenarios based on recycled platinum are also being evaluated.

The project partners will leverage these results to write up the ecodesign guides, which will be made available to hydrogen stakeholders to help them make informed decisions from the early technology development stages.

*Life cycle sustainability assessment of a proton exchange membrane fuel cell technology for ecodesign purposes," International Journal of Hydrogen Energy, 2023.